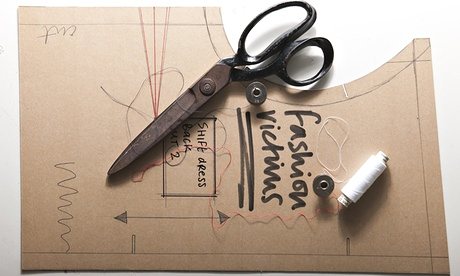

What is a Tech Pack?

The manufacturing process comprises of many different stages, and here at B&S we understand that those who are new to the clothing industry can find this a daunting and confusing task, with many different possibilities to choose from and stages to consider. But do not fear, we are here to help! This week we sat…