We recently sat down with one of our spec designers Jenny to talk through one of the most crucial stages of the manufacturing process- tech packs. This week we are discussing all things pattern cutting with one of our in-house pattern cutters Leonie.

Q: For those who are new to the manufacturing process, can you give a quick description of what pattern cutting actually is and why it is so important?

A: Pattern cutting is the process of producing a physical pattern for each garment which is then used as a template when cutting out the fabric before production. Pattern cutting is a vital step in garment production, and without a pattern it would be physcially impossible to create a garment.

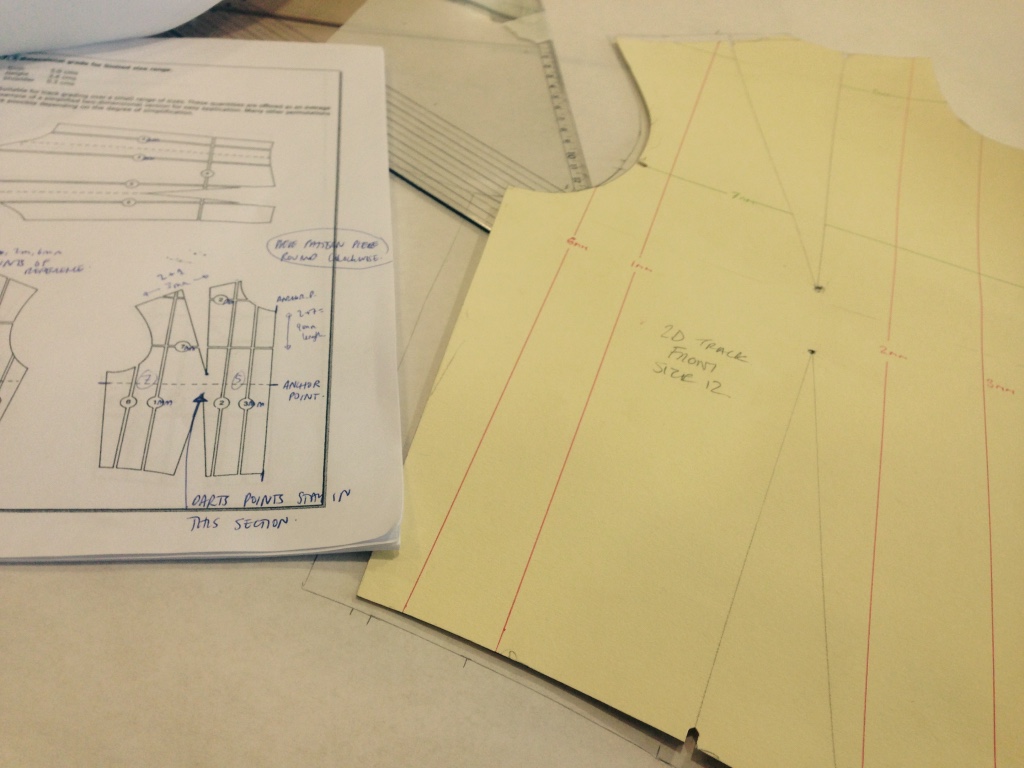

Some of equipment used during pattern cutting.

Q: What is the first step in being able to create a pattern?

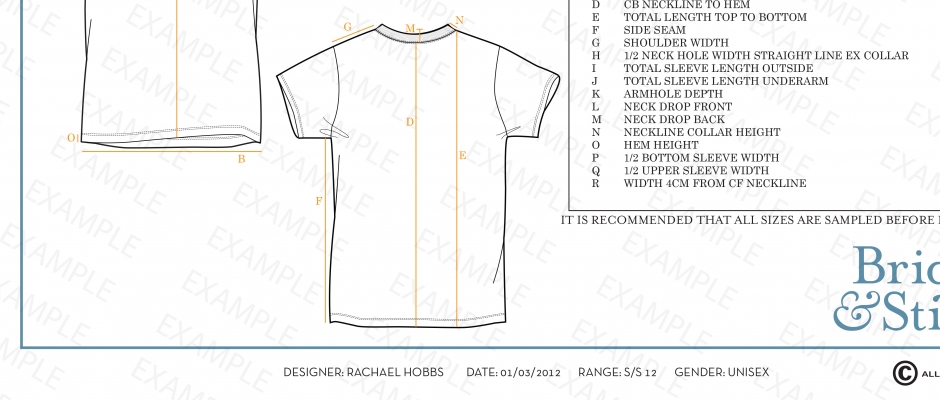

A: Design and manufacturing specifications for each garment must be completed first, as these basically serve as an instruction manual providing the pattern cutter with a concise description of all the features and requirements of the garment. We will initially produce the pattern in one size (we usually recommend the middle size), which is referred to as the master pattern. The manufacturing specification outlines all the measurements required to produce the master pattern.

We will produce all patterns in-house by hand or can outsource digital patterns upon request.

Example of a Manufacturing Specification showing all measurements required to produce the master pattern.

Q: Why do you create the master pattern first?

The master pattern allows you to assess the fit of the garment and suitability of the chosen fabric before any other sizes are produced. This ultimately saves both ourselves and our clients time and money. Once a master pattern has been created, it will be sent across to the chosen factory and go through sampling and then adjusted accordingly until the desired fit is achieved and approved.

Will always aim to produce master patterns as accurately as possible however it is unrealistic to expect first samples to be perfect. We usually expect at least two rounds of sampling for new styles, though depending on the complexity of the garment and the changes made, more could be needed.

Once the final fit has been approved we are able to grade the patterns.

Snap shot of our pattern rail! We produce all patterns in-house by hand on card.

Q: What is grading?

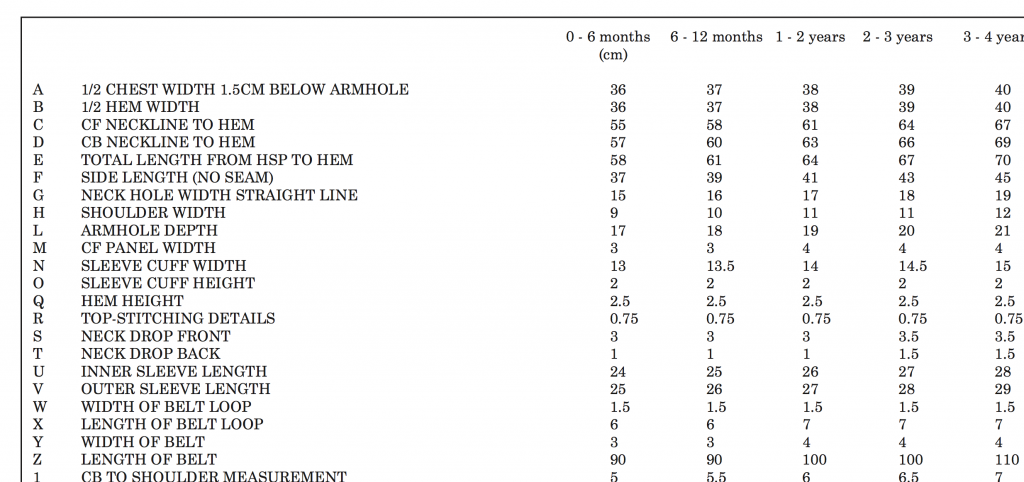

A: Grading is the process of increasing or decreasing the master pattern to produce additional patterns for each size in your size range. This is based on measurements provided in the grading specification which is included in the clients tech pack.

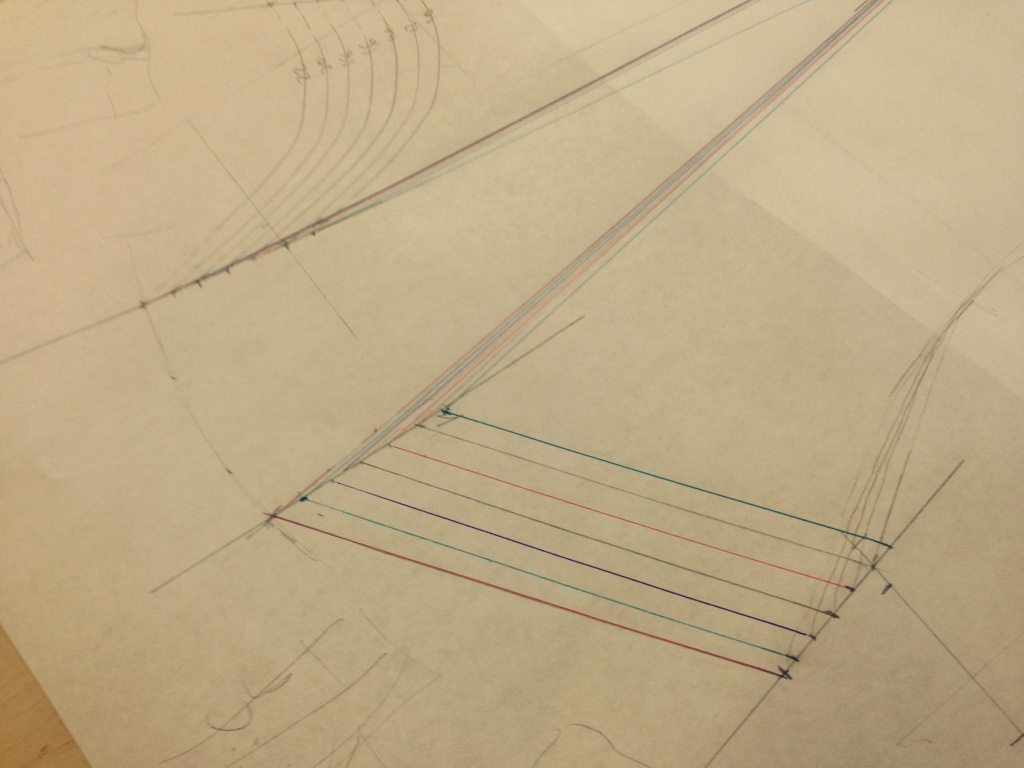

Graded ‘nest’ showing the different sizes

Q: How do you determine the measurements of the smaller/larger sizes?

A: The increase/decrease in measurements are referred to as increments and can will vary depending on the garment and specific customer base. We can either work from measurements provided by our clients, or use established measurements which meet British Standards.

Example grading specification showing the measurements for each size in the size range.

Q: How many sizes can a pattern be graded to?

A: We can grade patterns to whatever size range requested by our clients, however we would usually recommend 3-5 sizes are adequate for most garments.

Q: So what happens after the patterns have been graded?

A: Grading is the last stage in the pattern process so once this has been completed the graded patterns can be snd back to the factory ready for production!

Grading in progress!

Thank you Leonie for chatting with us today!

We hope you found that informative, and made the process of getting from sketch to finished garment a little more clear! Watch this space for more interviews with various members of the B&S team.