The manufacturing process comprises of many different stages, and here at B&S we understand that those who are new to the clothing industry can find this a daunting and confusing task, with many different possibilities to choose from and stages to consider. But do not fear, we are here to help!

This week we sat down with one of our spec designers Jenny to talk through one of the most crucial steps in the process, one that is often overlooked, tech packs.

So can you give us a quick sum-up of what is a tech pack?

A tech pack is an informative set of documents relating to the specific garment you are looking to produce. These documents can include design specs, manufacturing specs, grading specs, colour and artwork (PACART) sheets.

And what information is included in the spec sheets?

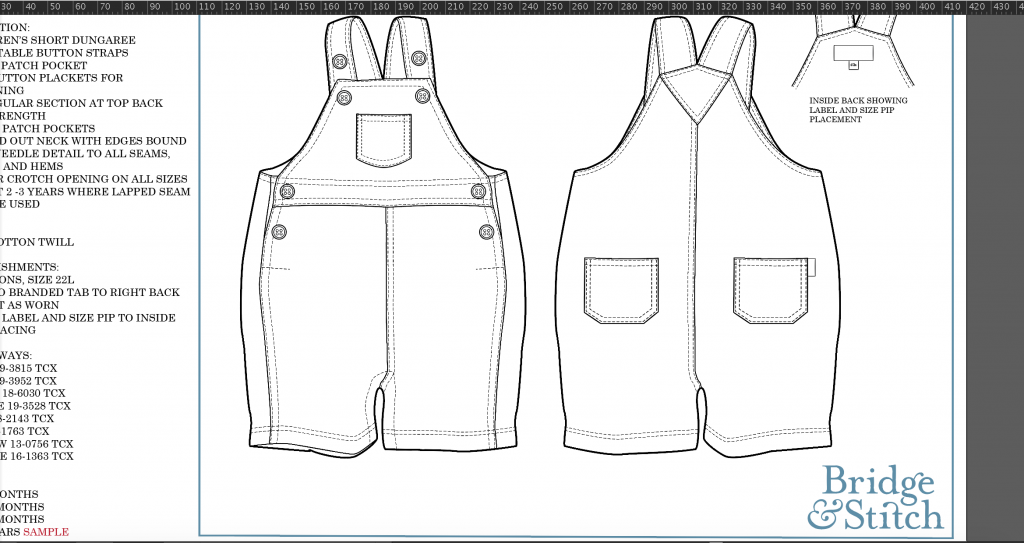

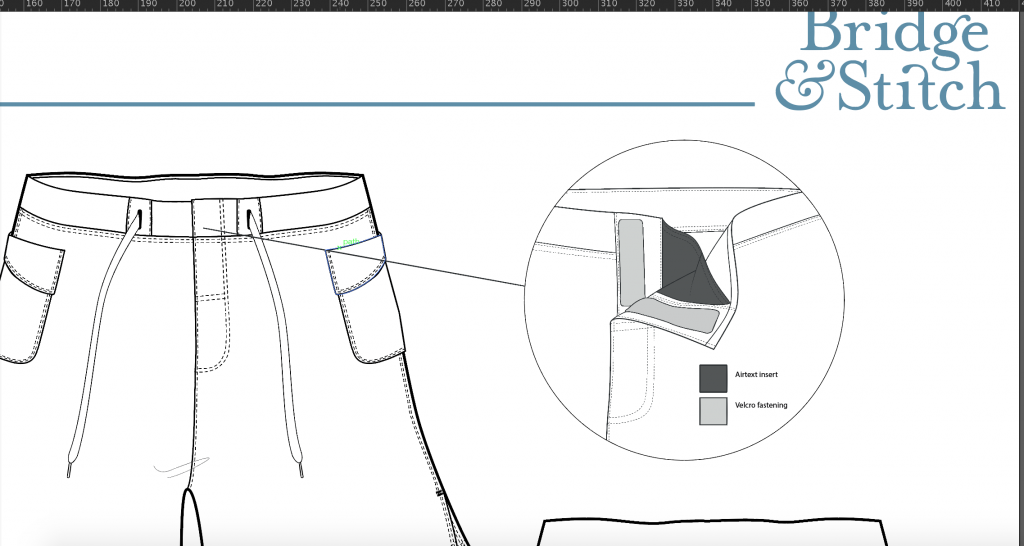

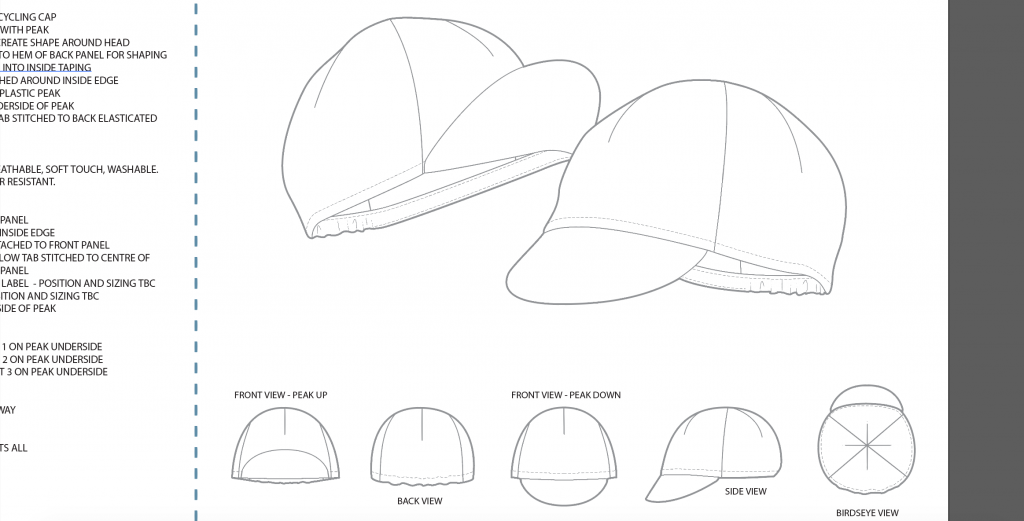

A design specification sheet is the first to be produced. This is made up of a technical drawing of your garment, showing front and back views, along with any other details necessary, for example inside construction, side views, close-ups of stitching or complex detailing. We then outline all aspects of the product, including an in-depth description of the construction, fabrics, trims & embellishments, colourways, size range and quantities.

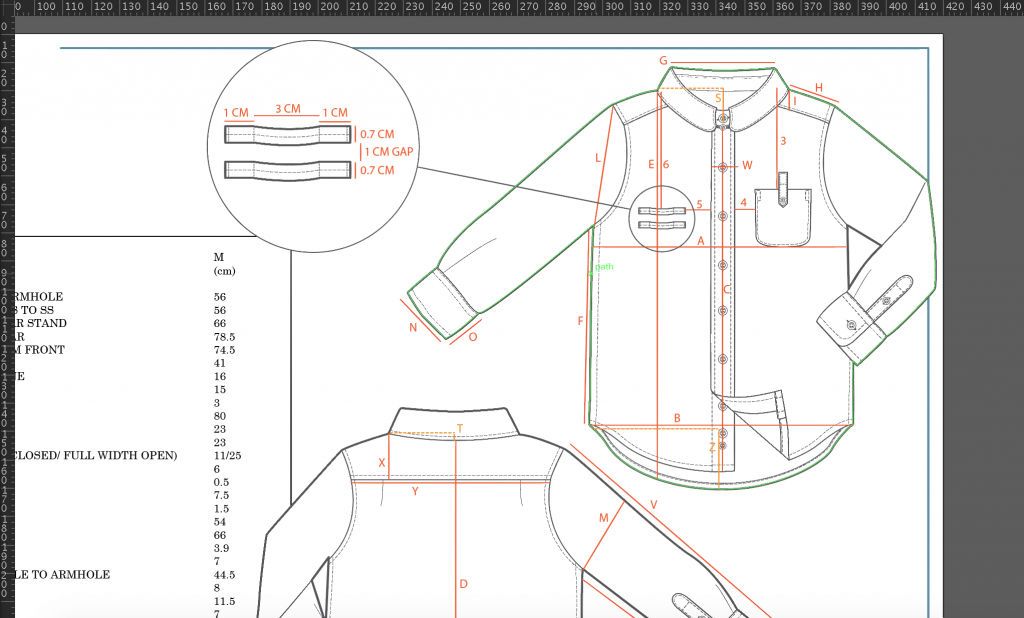

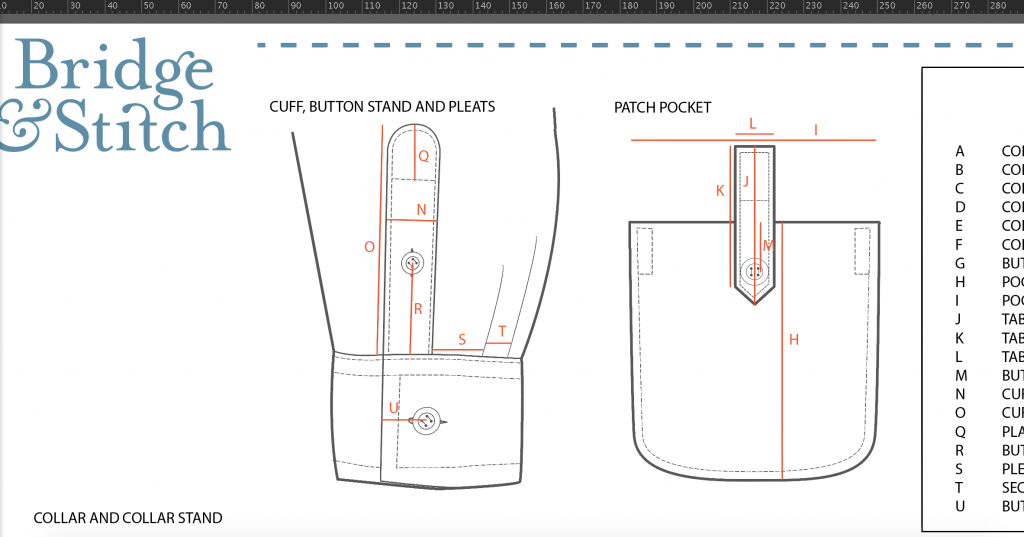

The technical drawing is then used as the basis for your manufacturing sheet. This is an illustrated list of all measurements of your product, in the sample size you require.

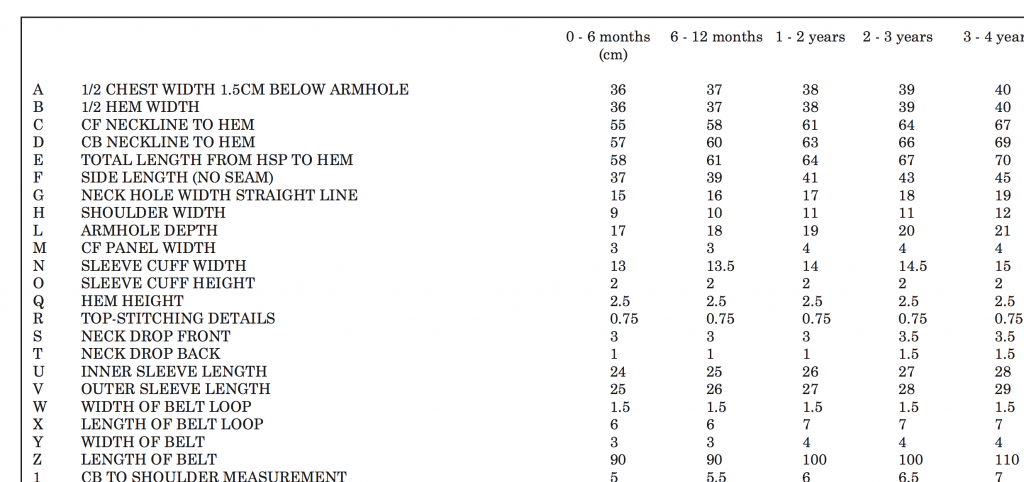

Once samples have been approved from the measurements on your manufacturing sheet, we can draw up a grading sheet, which grades each measurement up and down to the required size range you would like in your collection – for example; S, M, L, XL. We always wait to produce grading sheets until after the sample size has been approved, so that if any adjustments need to be made, they do not need to be applied to every size.

If necessary, we also produce colourway boards and artwork sheets known as PACART sheets. Colour boards illustrate all colourways your design is to be produced in. PACART sheets are information and technical drawings of any prints, embroideries, fabric design, branding, labels, swing tickets, appliques or any other embellishments included in your garment if required.

What information does a client need to provide for you to draw up a design specification?

This is completely dependent on what stage you are at with your design. If this is just an idea in your head, we can work with you from scratch to produce a design you are happy with. Usually, we work from a sketch, photo or existing garment as a starting point. It depends on the client.

How do you create a tech pack?

All specification sheets are produced on industry standard programs, Adobe Illustrator primarily. All tech packs are exported as a PDF, ensuring that these can be received and viewed by all computers.

PACART sheets are information and technical drawings of any prints, embroideries, fabric design, branding, labels, swing tickets, appliques or any other embellishments included in your garment.

Why do you need to produce tech packs?

Tech packs are a crucial tool for developing your designs. They are used to communicate with all parties involved in the creation of your product, from printers and fabric suppliers, to pattern cutters and factories. By producing specification sheets, you are ensuring that all communication regarding your garment is efficient and clear.

The design spec sheet is first used to gather production quotes from various factories we feel would be appropriate to manufacture your product. These initial quotes are usually only a guideline until the final costings can be confirmed once samples have been approved.

The manufacturing and grading sheets are provided as guides for the factory and pattern cutter, outlining all measurements they will need to know and reference throughout the process. Pattern cutters will use your manufacturing sheets to produce your master pattern, and grading spec sheets will form the basis for your graded patterns.

When we provide a tech pack with the sample pack (patterns, fabric and trims), we are ensuring that the factory has all the information they need to make an accurate sample, minimising errors, increasing their efficiency and essentially saving you time and money.

Ultimately, with a tech pack, suppliers and factories will be provided with a compact and concise information document, which should enable them to clearly understand your product without having to refer back to the designer, and without any aspects of your design being overlooked.

Magnified views allow for more complex or internal details to be explained.

Detailed view shows smaller but essential measurements for a shirt cuff and chest pocket

What is a master pattern?

A master pattern is a card template produced from your manufacturing spec sheet which the factory uses as a guide to cut around for each style. ‘Master’ refers to the size in which you are having your sample produced – we always recommend that this is the medium size.

Once the master pattern is approved, we then ‘grade’ this to the different sizes. These graded sizes are also produced in cards for the factory to cut around.

Snapshot of our pattern rail!

Are tech packs only for clothing?

No not at all, we can produce tech packs for a large range of textile products, including accessories, home furnishings, bags, fitness equipment and more.

We can produce tech packs for a large range of textile products, including sportswear accessories and home furnishings

How long do tech packs take to produce?

Depending on the quantity of designs and any deadlines you may be working towards, lead times for each sheet can be anywhere from 5 to 10 working days.

Do you also help with branding?

Yes, we can certainly work with you on your branding, this would be included in the PACART sheets. If required, we can then send these to our supplier for custom labels, swing tickets and packaging.

Grading sheets showing the whole size range of each product

Thanks, Jenny!

Watch this space for more interviews with various members of the B&S team, where we will be discussing all aspects of the production process, from Made in Britain clothing to a range of other specific clothing manufacturing services.