In the world of clothing development and manufacturing, understanding the nitty-gritty details is crucial and one of the most vital aspects is manufacturing specifications. Whether you’re a seasoned manufacturer or just stepping into the industry for the first time, understanding the concept of manufacturing specifications is fundamental. So, what exactly are manufacturing specifications, and why do they matter?

Well, manufacturing specification, in essence, refers to a detailed document outlining the standards, requirements, and procedures to be followed during the production of a particular item. It serves as a blueprint that guides manufacturers through the entire production process, ensuring consistency, quality, and adherence to standards.

A manufacturer specification sheet, often referred to as a spec sheet, is a comprehensive document that provides precise instructions regarding dimensions, tolerances, shrinkage allowance and other essential details relevant to the production process.

Manufacturing specifications are a key element of tech packs, which contain intricate details specific to garment production, such as fabric type, construction and stitching techniques, sizing charts, and labelling requirements. They play a pivotal role in ensuring that every piece of clothing meets the desired standards in terms of fit, durability, and aesthetics.

Why is a manufacturing specification needed?

A professional, accurate manufacturing specification is a vital aspect of the production process for several reasons. Some of these include:

- Quality Assurance: Manufacturing specifications set the benchmark for quality. By clearly defining standards and procedures, they minimise deviations and defects, ensuring that the end product meets customer expectations.

- Consistency: Consistency is key in clothing manufacturing. With detailed specifications in place, manufacturers can replicate processes accurately, maintaining uniformity across batches and minimising variability.

- Cost Efficiency: Clear specifications help streamline the production process, reducing waste, rework, and associated costs, particularly during the sampling process. This also benefits lead times and reduces timescales.

- Regulatory Compliance: In many industries, adherence to regulatory standards is non-negotiable. Manufacturing specifications ensure that products meet legal requirements, safeguarding against potential fines, penalties, and reputational damage.

- Customer Satisfaction: Ultimately, the goal of manufacturing is to deliver products that satisfy customers. Well-defined specifications help meet customer expectations regarding quality, performance, and functionality, fostering trust and loyalty.

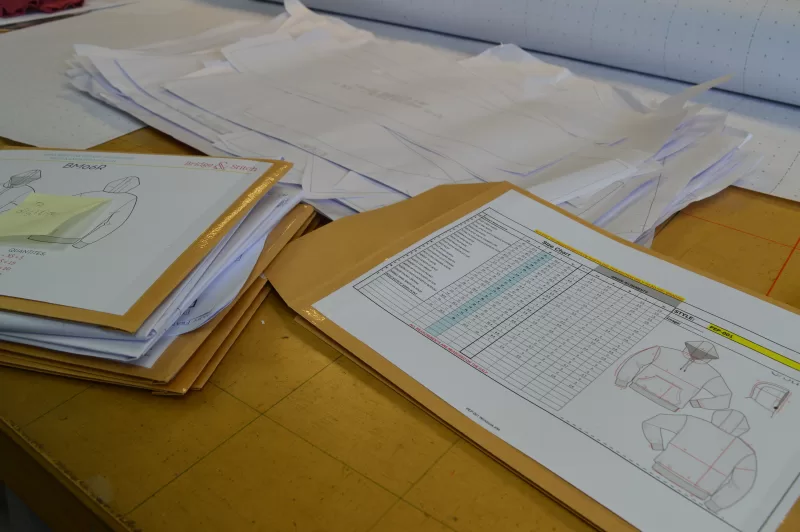

[example of a manufacturing specification]

Manufacturing specification tips

Creating effective manufacturing specifications requires attention to detail and collaboration across various departments. If you’re just starting in the clothing manufacturing industry and want to know how to produce manufacturing specifications correctly, here are some tips for you.

- Ensure that specifications are clear, concise, and unambiguous. Use precise language and include detailed illustrations or diagrams where necessary.

- Regularly review and update specifications to reflect changes in materials, processes, or size. Keeping specifications current is essential for maintaining relevance and accuracy.

- Involve key stakeholders, including designers, pattern cutters, garment technologists and manufacturers, in the specification development process. Their input and expertise will enrich the document.

- Establish a system for document control to manage revisions, approvals, and distribution effectively. This ensures that all stakeholders have access to the latest version of the specifications.

- Use experts to complete your manufacturing specifications if this is an area that you haven’t had prior experience in. Please get in touch with Bridge & Stitch for more information.

In summary, manufacturing specifications serve as the cornerstone of efficient and quality-driven production. From defining materials and dimensions to outlining procedures and standards, these documents play a pivotal role in ensuring consistency, compliance, and customer satisfaction. By understanding and implementing effective manufacturing specifications, clothing manufacturers can optimise their processes, minimise risks, and deliver exceptional products that consumers love!